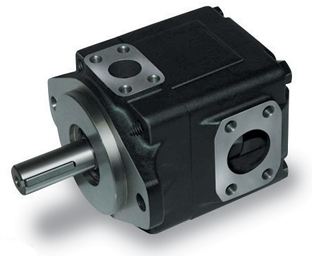

Denison Vane Pumps

Configure Denison Hydraulics Vane Pumps Yourself!

To configure Denison Hydraulics vane pumps, you will usually need to consider various specifications and parameters depending on your specific requirements. While I can give you an overview of the setup process, please note that the exact steps may vary depending on the model and series of Denison Vane Pump you are working with. It is recommended that you review the product documentation or contact the manufacturer for exact instructions.

These are the general steps followed in setting up Denison Hydraulics vane pumps:

- Pump Selection Series – Denison Hydraulics offers several series of vane pumps including Gold Cup, Premier, and P6. Select the chain that best fits your application based on factors such as flow rate, pressure rating, and other performance requirements.

- Select Pump Size – Within the series you have chosen, there are usually several sizes available. The size of the pump determines the displacement or flow capacity of the pump. Consider the flow requirements for your application and choose the appropriate pump size accordingly.

- Select Mounting Type – Dennison vane pumps can be configured with a variety of mounting options, including flange, foot, or stack mounts. Select the type of installation best suited to your installation requirements and system design.

- Select Column and Port Options – Select the desired column type and size for your application, such as keyed or notched columns. Also, choose port options (suction and pressure ports) based on the desired inlet and outlet connections in your hydraulic system.

- Consider Additional Features – Dennison vane pumps may offer optional features such as integrated relief valves, pressure compensators, or flow control valves. Evaluate if any of these features are required for your application and configure them accordingly.

- Check System Compatibility – Ensure that the selected Denison Vane pump is compatible with the rest of the hydraulic system, including the power supply, reservoir, filters, and other components. Consider factors such as system pressure, fluid compatibility, and overall system design.

- Consult Technical Documentation – Refer to product data sheets, technical manuals and installation guides provided by Denison Hydraulics. These resources will provide detailed information on specific configuration options, performance curves, and installation procedures for your chosen vane pump model.

- SEEK EXPERT ADVICE: If you are unsure about any aspect of the setup process or need assistance selecting the right pump for your application, it is recommended that you consult Denison Hydraulics or an authorized distributor. They can provide expert guidance and support to ensure optimal pump selection and configuration.

Remember, proper installation, maintenance, and operation are essential to the performance and longevity of your hydraulic pumps. Always follow the manufacturer’s instructions and best practices for safe and reliable operation.

Denison Fine Technology

Denison Hydraulics, now part of the Parker Hannifin Corporation, is known for its innovative vane pump technology. Dennison vane pumps are widely used in many hydraulic applications due to their efficiency, reliability and compact design. Here are some of the key aspects of Dennison vane pump technology:

- Balanced Vane Design – Dennison vane pumps feature a balanced vane design that ensures smooth and efficient operation. Vanes are often made of self-lubricating materials, such as carbon or composites, to reduce friction and wear.

- Dual Vane Configuration – Dennison vane pumps often use a dual vane configuration, where two vanes work in tandem to create a balanced distribution of force. This design helps reduce vibration, noise and pressure fluctuations in the hydraulic system.

- Multiple Vane Angles – Dennison vane pumps offer multiple vane angles to suit different system requirements. By adjusting the vane angle, the pump can be optimized for specific flow rates, pressure rates and efficiency levels.

- Sturdy Construction – Dennison vane pumps are built with premium quality materials and precision manufacturing processes to ensure durability and a long life. The pump casing and components are designed to withstand high pressure conditions and provide reliable performance even in demanding applications.

- High Efficiency and Performance – Dennison vane pumps are designed to achieve high volumetric efficiency, minimize energy losses and maximize system performance. They can provide constant flow rates and pressures, allowing for precise control and operation of hydraulic systems.

- Wide Range of Options – Denison offers a wide range of vane pump models and sizes to meet the demands of diverse applications. These pumps can be configured with different mounting options, shaft types, outlet directions, and optional features such as compensators or integrated relief valves.

- COMPATIBILITY AND INTERCHANGABILITY: Dennison vane pumps are engineered to be compatible with industry standard dimensions and specifications, making them interchangeable with other vane pumps on the market. This allows for easy replacement or integration into existing hydraulic systems.

Dennison hydraulic pump technology has been widely used in industries such as mobile equipment, industrial machinery, and aerospace, among others. Their reputation for reliable performance and efficient operation has made Denison vane pumps a popular choice for hydraulic system designers and operators.

T6E-085-2R00-C1

T6E-085-1R00-C1

T6E-072-3R03-A1

T6E-072-3R02-A1

T6E-072-3R02-A1

T6E-072-2R00-C1

T6E-072-1R02-A1

T6E-072-1R01-A1

T6E-072-1R00-C1

T6E-072-1R00-A1

T6E-072-1L01-A1

T6E-072-1L00-A1

T6E-066-2R02-A1

T6E-066-2R00-C1

T6E-066-1R02-A1

T6E-066-1R01-A1

T6E-066-1R00-C1

T6E-066-1R00-A1

T6E-066-1L02-A1

T6E-062-3L02-A1

T6E-062-2R00-C1

T6E-062-1R03-A1

T6E-062-1R01-B1

T6E-062-1R01-A1

T6E-062-1R00-C1

T6E-062-1R00-A1

T6E-062-1L01-A1

T6E-052-2R00-C1

T6E-052-1R03-A1

T6E-052-1R02-A1

T6E-052-1R00-C1

T6E-050-2R00-C1

T6E-050-1R00-C1

T6E-050-1R00-A5

T6E-050-1R00-A1

T6E-045-2R00-C1

T6E-045-1R00-C1

T6E-042-2R00-C1

T6E-042-1R01-A1

T6E-042-1R00-C1

T6D-B38-1R00-B1

T6D-050-2R02-B1

T6D-050-2R02-B1

T6D-050-2R00-C1

T6D-050-1R00-C1

T6D-045-2R01-B1

T6D-045-2R00-C1

T6D-045-1R00-C1

T6D-042-2R02-B1

T6D-042-2R00-C1

T6D-042-1R01-B1

T6D-042-1R00-C1

T6D-038-2R00-C1

T6D-038-1R00-C1

T6D-035-2R00-C1

T6D-035-2R00-B1

T6D-035-1R01-B1

T6D-035-1R00-C1

T6D-035-1L00-B1

T6D-031-2R02-B1

T6D-031-2R01-B1

T6D-031-2R00-C1

T6D-031-1R00-C1

T6D-028-1R00-C1

T6D-024-2R00-C1

T6D-024-1R00-C1

T6D-020-2R00-C1

T6D-020-1R01-B5

T6D-020-1R00-C1

T6D-017-2R00-C1

T6D-017-1R00-C1

T6D-014-3R00-B1

T6D-014-2R00-C1

T6C-031-2R01-B1

T6C-031-2R00-B1

T6C-031-2R00-B1

T6C-031-1R03-B1

T6C-031-1R03-B1

T6C-031-1R00-B1

T6C-031-1R00-B1

T6C-028-2R01-B1

T6C-028-1R02-A1

T6C-028-1R00-B1

T6C-025-1R03-B1

T6C-025-1R02-B1

T6C-025-1R01-B1

T6C-025-1R00-B1

T6C-022-2R00-C1

T6C-02-1R03-B1

T6C-02-1R02-B1

T6C-02-1R00-B1

T6C-020-2R01-B1

T6C-020-2R00-C1

T6C-020-2R00-B1

T6C-020-1R02-B1

T6C-020-1R00-C1

T6C-020-1R00-B1

T6C-017-3R01-B1

T6C-017-3R00-B1

T6C-017-2R01-B1

T6C-017-1R02-B1

T6C-017-1R00-B1

T6C-017-1L00-B1

T6C-014-2R02-B1

T6C-014-2R02-B1

T6C-014-2L01-B1

T6C-014-1R02-B1

T6C-014-1R02-B1

T6C-014-1R00-C1

T6C-014-1R00-B1

T6C-012-1L01-B1

T6C-010-2R02-B1

T6C-010-2R01-B1

T6C-010-1R01-B1

T6C-010-1L00-B1

T6C-008-3R02-B1

T6C-008-2R02-B1

T6C-008-2R01-B1

T6C-008-2R00-B1

T6C-008-1R01-B1

T6C-006-2R00-C1

T6C-003-1R01-A1