We are aware that a pump is a mechanically powered tool used to elevate, transfer, and compress fluids. Many different industries, including mining, the chemical industry, the automobile industry, and others, rely heavily on pumps. For various uses, the industry offers a wide range of pumps. Based on the technique utilized to transfer the fluids, they are usually divided into two categories.

- Dynamic pumps and non-positive displacement pumps

- Pumps with positive displacement

When using a positive displacement pump, the fluid moves at a fixed speed regardless of the inlet pressure. The hydraulic pump can therefore be categorized as a positive displacement pump. We can discover more about hydraulic pumps right here.

The Rexroth hydraulic pump built into the hydraulic system is capable of raising, lowering, opening, and closing components, among other tasks. According to your needs and functions, such as working medium, required pressure range, motor type, etc., a variety of hydraulic pumps are offered on the market. The hydraulic pumps are run on the displacement concept. The most often used hydraulic pumps are the gear pump, piston pump, and vane pump.

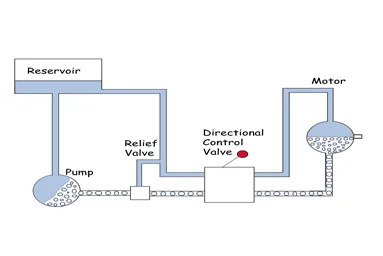

Although Rexroth hydraulic pumps transform mechanical energy into hydraulic energy, its use is similar to that of other types of pumps. How are hydraulic pumps operated? The hydraulic pump has two steps to it operation. Mechanical action first creates a vacuum at the pump’s inlet, which causes atmospheric pressure to force the liquid from the reservoir into the inlet line. Second, the fluid is forced into the hydraulic system from the pump outlet by mechanical action.

The hydraulic drive system’s major components are hydraulic cylinders, pumps, and motors. The hydraulic pump and motor share a similar architecture, although they serve different purposes. A hydraulic motor transforms hydraulic pressure into torque or spin, while a hydraulic pump transforms mechanical energy into hydraulic energy. Due to their comparable designs, some hydraulic pumps with set displacement sizes can also be employed as hydraulic motors. Winches, crane motors, self-propelled cranes, excavators, mixer and agitator motors, roller mills, etc. all require hydraulic motors.

Read Also About: Eaton hydraulic pump

An essential part of the hydraulic system is the hydraulic pump. Any slight flaw in the pump will have a negative impact on the system’s precision and accuracy. Construction materials are chosen based on the temperature and pressure that the hydraulic system will experience in order to minimize wear and give maximum performance. High-pressure hydraulic systems use titanium alloys and polymers, while other production materials include plastics, synthetic rubbers, alloys, etc. Therefore, before investing in a pump, always conduct a thorough needs analysis.